BREAD

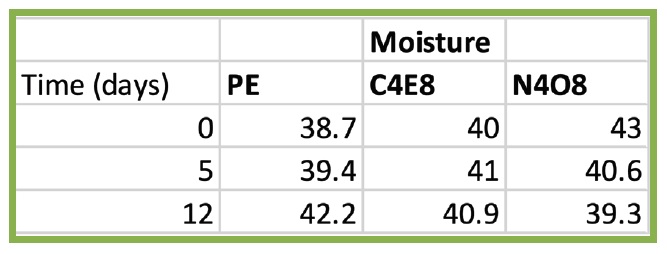

MOISTURE ANALYSIS

After 12 days, the bread in the untreated PE bags was more humid than the bread in the PE bags coated with either filler. The higher moisture level in the untreated PE bags caused mold to multiply on the bread.

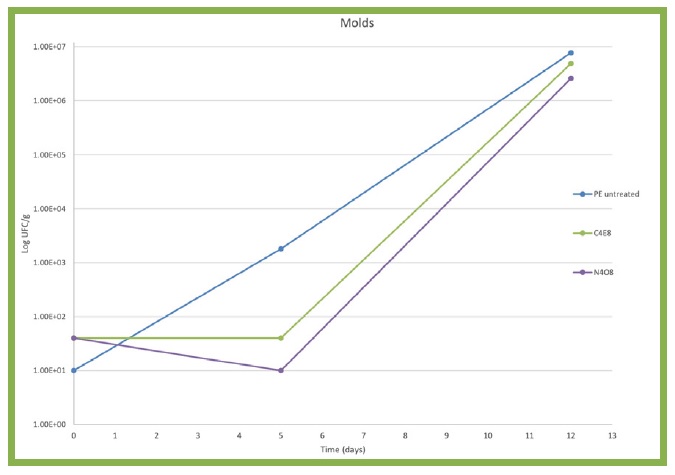

MICROBIOLOGICAL ANALYSIS

TEST CONDITIONS

12 days at room

humidity and temperature

FILLERS

N4O8 and C4E8

Application: Coating

TYPE OF PACKAGING

PE bags coated with N4O8 or C4E8 fillers

Sample referenced: Untreated PE bags

After just 5 days, the amount of mold on the bread in the untreated PE bags was far more than the bread in the PE bags coated with C4E8 or N408 fillers. This difference was even clearer after 12 days. These results show that the fillers slowed down the spread of mold on bread.

RESULTS

Organoleptic analysis

Shelf-life Study: fresh white bread in untreated PE bags for 12 days at room temperature.

Result: 5 out of 6 parts had some mold; 15% was covered in mold (on average). The bread was soft, only slightly hardened.

Shelf-life Study: fresh white bread in PE bags treated with N408 for 12 days at room temperature.

Result: 1 out of 6 parts had 1 mold. The bread was soft, only slightly hardened.

Shelf-life Study: fresh white bread in PE bags treated with C4E8 for 12 days at room temperature.

Result: All parts were OK. The bread was soft, only slightly hardened.

TEST CONDITIONS

12 days at room

humidity and temperature

FILLERS

N4O8 and C4E8

Application: Coating

TYPE OF PACKAGING

PE bags coated with N4O8 or C4E8 fillers

Sample referenced: Untreated PE bags